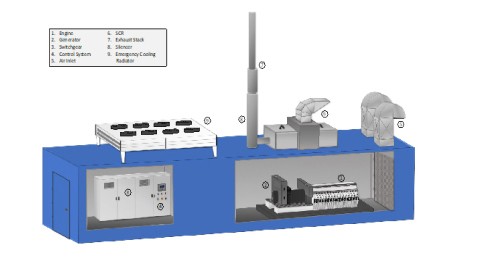

Engine Retrofits

When it comes to Return on your investment, there's no better way than to enroll an engine in a program that earns you money by reducing the demand you put on the electric grid. The quickest path to this is through the addition of emission reduction equipment

Energy Choice has the experience take you through all the necessary steps to get an engine upgraded, re-permitted, tested and certified to enroll in a revenue-generating energy program.