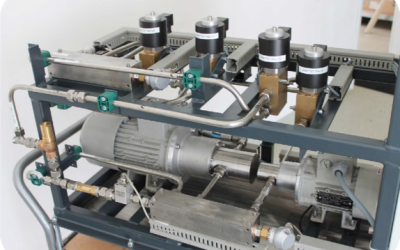

Fuel Water Emulsion (FWE) is a pre-treatment technology designed to lower fuel consumption and air emissions in diesel fired engines. FEW is an add-on circulation system, utilizing fully electronic controls and monitoring systems, designed to blend water with diesel fuel immediately before the fuel injection pump. The fuel is taken from the existing fuel supply system and pre-mixed with varying, previously specified amounts of specially treated fresh water. This pre-treatment allows customers to maximize the benefits of the unit, according to the desired output.

Environmental and Economic Benefits of Diesel Water Emulsion

Water-emulsified diesel is a substantial advancement in fuel alternatives. The emulsion has the ability to improve the emissions that come from diesel engine fuel combustion. Further, many studies suggest that a diesel water fuel emulsion plays a role in improving the combustion within a diesel engine.

What is Diesel Water Emulsion?

To best understand what a diesel water emulsion is, we first must discuss the process of emulsifying liquids. Chemically speaking, an emulsified liquid, also known as a dispersion, is a liquid in which distributed particles of one material are dispersed in another material.

A diesel water emulsion is a mixture of water, diesel fuel, and several additives. It’s important to note that diesel fuel, which is an oil, cannot dissolve in water. This means that when water is dispersed into diesel fuel, it can be emulsified but they will never form a homogeneous liquid.

Where are emulsified fuels used?

The mixture of water, diesel fuel, and several additives, known as the diesel water emulsion, can be used in any diesel engine.

However, it is important to understand that because water has been added to the fuel mixture, the energy that the generator can produce is reduced. Emulsified fuels have a tradeoff where a greater reduction in emissions will correspond to a greater reduction in the generator capacity. The capacity reduction will vary depending on the emissions levels that are trying to be achieved, but typical capacity reductions are around 10-35%.

Often, the combination of using a diesel water emulsion with an efficient diesel generator provides better fuel consumption of the emulsion. In many cases, the benefits of the better fuel consumption and the reduction in harmful engine emissions far outweigh the less-than desirable power reduction of the engine. Beyond the ability to use diesel emulsions as a fuel source, there are secondary benefits, including the mitigation of the high temperatures resulting from combustion as well as the reduction of emissions.

Decreased Combustion Temperatures

In many cases, it is desirable to reduce and control the amount of heat that an engine or generator produces under load. Increased heat can cause premature engine component wear, the breakdown of fluids, and the reduction of the usable lifetime of the equipment. Many studies have shown that using a diesel emulsion as a fuel source can effectively decrease the combustion temperature which yields all of the benefits of a lower operating temperature including the increased engine efficiency, reduced component wear, and increase in the lifetime of the equipment.

The other main benefit of fuel water emulsion decreasing the operation temperature is that this can increase the thermal efficiency of the engine. By definition, thermal efficiency is the ratio of work done by an engine to the amount of heat produced by the fuel and engine over the same work-time. Increased thermal efficiency means cooler running equipment and improved fuel consumption.

Lower NOx Emissions

One of the primary initiatives of the United States’ Clean Air Act and its amendments is the reduction of NOx emissions. The U.S. Environmental Protection Agency has cited that industrial facilities can and should make efforts to reduce NOx emissions from sources that include combustion equipment like diesel generators.

Studies of NOx emissions have demonstrated their role in forming ground-level ozone. This ozone can have adverse health effects on humans and other living organisms and pollutes the environment. Reducing NOx emissions can effectively reduce ground-level ozone.

While there are many technologies available to control NOx emissions, their application is mostly site-specific and dependent on the conditions of the facility. Replacing heavy fuel oils with a diesel water emulsion can effectively reduce NOx emissions and has little physical impact on the facility or equipment.

Some case studies suggest that emulsified diesel fuel can effectively reduce emissions of NOx by about 10-70 percent and particulate matter, also known as PM, by as much as 80 percent.

Energy Choice Can Help

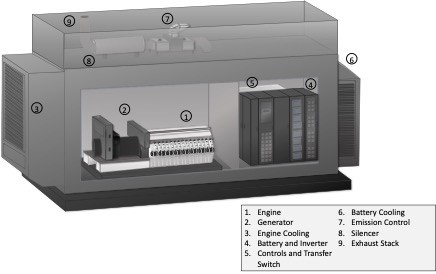

We combine onsite power generation with emissions control technologies to create highly efficient modular power generation. As part of our methodology, we work closely with project developers and engine end-users to provide a full turn-key project. Our power generation units can either be power only or combined heat and power (CHP).

We can provide emission control techniques and equipment or full turn-key emission reduction that will ensure power generation units comply with environmental requirements, including the EPA requirements for demand response.

Fuel Water Emulsion: parallel, energy efficient reduction of all relevant pollutant’s benefits:

Soot reduction up to the detection limit (≈ 100%)

Particle mass reduction of over 80%

Particle numbers reduction of over 90%

Up to 40% NOx reduction

Fuel consumption and – / CO2 – Reduction of 2 to 10% and more

No secondary emissions, e.g. NO2 / literature: significant reduction of PAH

Customers typically see a reduction in total running costs

Complete tolerance to poor fuel qualities / also HFO suitable

Savings in installation space

Ability to incorporate an SCR downstream

Significant running cost advantage in combination with SCR, compared to SCR only

Significant reduction of running cost in combination with SCR, compared to DPF & SCR

Cleaning effect for engine components, turbo charger, exhaust system

No additional heat dissipation in engine room

Guaranteed safe operation due to consistent monitoring and controls

Go Back

Go Back