To meet federal and/or state emissions standards, you can utilize one, or a combination of several different technologies, including oxidation catalysts, diesel particulate filters, fuel water emulsion, three-way catalysts and SCR systems. Energy Choice designs, sell, install and tests various technologies to bring under compliance existing or new assets.

Oxidation Catalysts

Oxidation catalysts are a form of emissions control systems that convert pollutants like carbon monoxide (CO) and hydrocarbons (HC) into carbon dioxide and water. These types of catalysts are widely utilized for both new and retrofitting existing installations. This is due to RICE NESHAP federal regulations. By installing an oxidation catalyst, or a diesel oxidation catalyst (DOC), customers become compliant with federal regulations and reduce their carbon footprint.

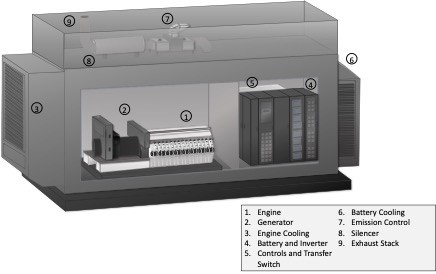

An emissions control system that is designed for NESHAP compliance would include an oxidation or diesel oxidation catalyst, a closed crankcase ventilation system (CCV), and a NESHAP monitoring device. This turn-key installation process allows our customers to revitalize existing generation assets and enroll in incentive-driven programs like Demand Response or Capacity Tag Management.

Selective Catalytic Reduction Systems (SCRs)

SCR (Selective Catalytic Reduction) System is typically used in power applications to remove nitrogen oxides (NOx) from exhaust gases. SCRs are successfully used today to reduce emissions on power generation engines, turbines, industrial boilers and diesel automobiles. They are employed in a variety of applications, including systems that operate on natural gas, bio/waste gases, and diesel fuels.

For new generation systems with expected higher run hours annually, the first component in an emissions control system is typically a Selective Catalytic Reduction (SCR) system. A SCR system injects a liquid agent like urea (DEF) through a catalyst into exhaust to set a chemical reaction to reduce NOx and CO by up to 97%. DEF is a non-toxic fluid composed of purified water and urea. An SCR system consist of:

– Dosing Systems: Adds the reactant (urea) to the exhaust gases

– Injection/mixer unit: Mixes the reactant with the exhaust gas

– Reactor Unit: Houses the catalyst

Following dosing process, all the pollutants in the exhaust gas are converted into nitrogen and water. Our SCR systems are finely tuned to meet the guaranteed emissions requirements and employ highly sophisticated dosing systems to avoid any harmful ammonia slip.

EC emissions control systems are a customized and packaged to allow for lower costs and quick installation. They include an emissions analyzer, dosing system, catalysts, filtration elements, urea tanks and all necessary accessories and components.

Fuel Water Emulsion (FWE)

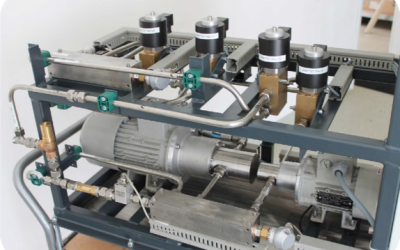

Fuel Water Emulsion (FWE) is a pre-treatment technology designed to lower fuel consumption and air emissions in diesel-fired engines. An EC FWE reduces NOx up to 70%, soot up to 100%, particle mass over 80%, CO2 up to 10%. In addition to lowering diesel engine emissions, with engine running cooler, FWE will improve engine life, performance and extend service schedules. It has a cleaning effect for engine components, turbocharger and exhaust system. Highly compact system save space and allow roof or on-site installations.

FWE is an add-on circulation system, utilizing fully electronic controls and monitoring systems, designed to blend water with diesel fuel immediately before the fuel injection pump. The fuel is taken from the existing fuel supply system and pre-mixed with varying, previously specified amounts of specially treated freshwater. This pre-treatment allows customers to maximize the benefits of the unit.

Energy Choice’s FWE lowers costs significantly compared to an SCR used in diesel engine retrofits in both upfront and maintenance costs.

Diesel Particulate Filter (DPF)

For diesel generators, the second component that an EC SCR system is a Diesel Particulate Filter (DPF). A DPF is utilized to reduce the amount of fine particles that are produced by a diesel engine. These systems are used in combination with an Energy Choice SCR to provide a complete package that allows existing diesel asset to meet the increasingly strict state and federal emissions standards.

Non-Selective Catalytic Reduction | 3-Way Catalyst (NSCR)

A 3-way catalyst reduces nitrogen oxide emissions, hydrocarbons and carbon monoxide and are used on rich burn gas engines to reduce emissions to compliance levels.

Energy Choice’s 3-way catalyst is customized to specific generation asset and is supplied as a single housing.

Continuous Parametric Monitoring Systems (CPMS)

Monitoring systems records and reports temperature and pressure data at catalyst bed from individual regulated stationary sources over 500 HP. In order to demonstrate compliance with federal, state and local environmental requirements, reporting will become an ongoing operating procedure. Minimum standards for measurement frequency, sensor accuracy, compliance tolerance, operational load, and periodic performance evaluations are set prior to testing and can be asset-specific.

CPMS is checked when tests are performed for the asset. Site-specific monitoring plan is developed and implemented by involving maintenance protocols for the CPMS. In addition, data review helps facility manager take corrective action when needed.

A CPMS from Energy Choice is modified so the required compliance information is easy collected and can be transferred remotely to your online Energy Choice account.

Go Back

Go Back